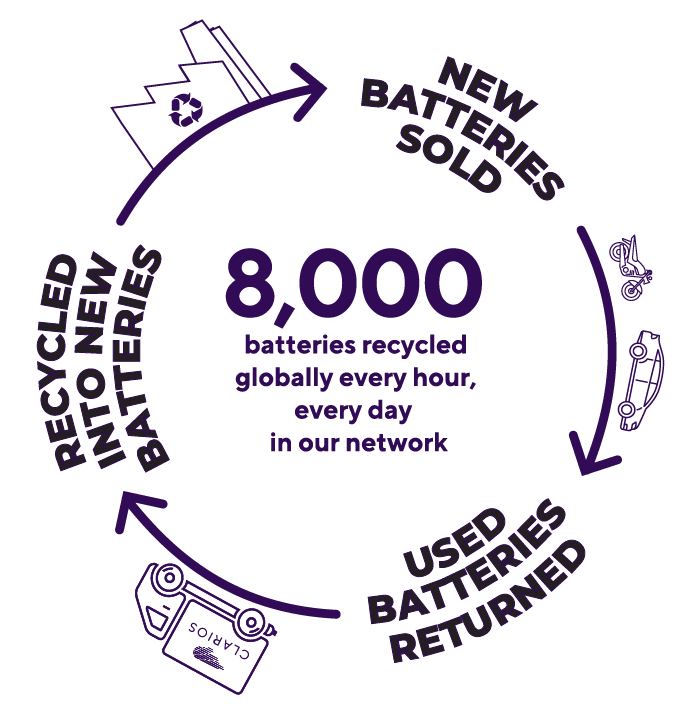

Recycling Process

Your old battery may be out of power, but it doesn’t belong in the back of your garage. Recycle it instead. Recycling conserves resources by recovering plastics and metals to create new batteries. The process begins when used batteries are collected from drop-off locations and transported to recycling centers.

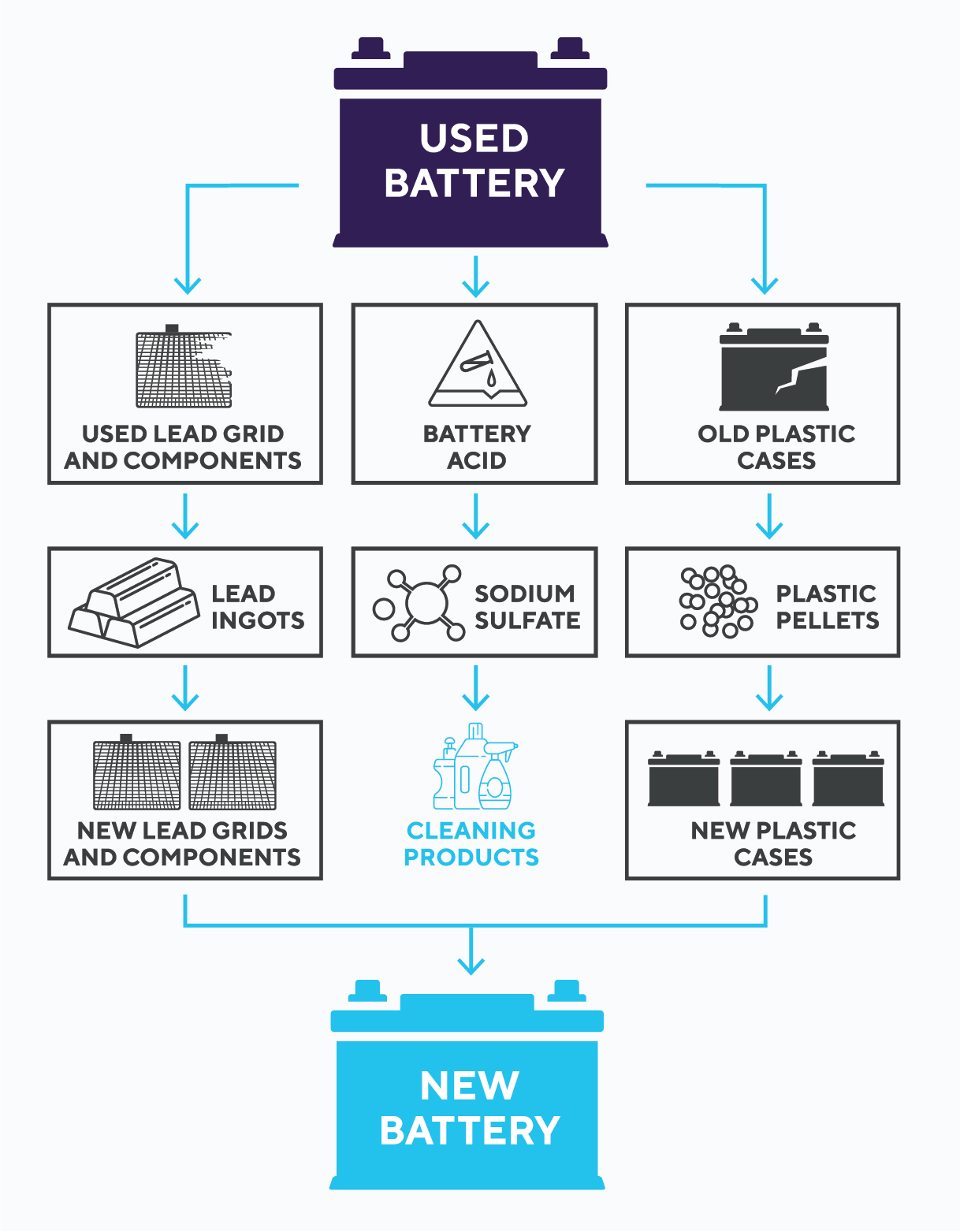

Clarios Battery Recycling Process

- Battery Collection: Used lead-acid batteries are collected and transported to a recycling facility.

- Breaking the Battery Apart: The batteries are broken into pieces to separate their components.

- Separating Materials: Lead and heavy metals are separated from the plastic. Plastic (polypropylene) is collected for reuse.

- Processing the Lead: The recovered lead is melted into lead ingots and reused to make new lead plates and components for future batteries.

- Recycling the Plastic: The plastic is formed into pellets and molded into new battery cases.

- Reclaiming the Acid: The old battery acid is neutralized and converted into sodium sulfate, which is used in detergents, glass, and textile manufacturing.

Vehicle Battery Recycling

Recycling old vehicle batteries helps reduce waste and conserves resources. Up to 99% of a lead-acid battery can be recycled, minimizing the need for new raw materials.

- Leave it with the counterperson when you buy a new one

- Drop it off at a local battery retailer

Most automotive retailers offer a credit for returning your used battery when purchasing a replacement. Always follow safety precautions when handling used batteries.

What About Lithium-Ion Batteries?

As electric vehicles and hybrid systems grow in popularity and more low voltage lithium batteries are in the market, lithium-ion battery recycling is becoming increasingly important. The process is different but just as essential.

Lithium-Ion Battery Recycling Process:

Safe Disassembly

Batteries are first safely discharged and dismantled in a controlled environment to avoid fire or chemical hazards.

Shredding & Sorting

The batteries are shredded to break them into small pieces. Automated systems separate materials like:

- Cobalt

- Lithium

- Nickel

- Copper

- Plastics

Thermal or Chemical Treatment

Processes like pyrometallurgy (high heat) or hydrometallurgy (using liquids) are used to extract and purify the metals.

Recovery & Reuse

The recovered materials are then used to manufacture new lithium-ion batteries, supporting a more circular battery economy.

Did you know vehicle batteries are the most recycled consumer product in the world?

Learn More